Share

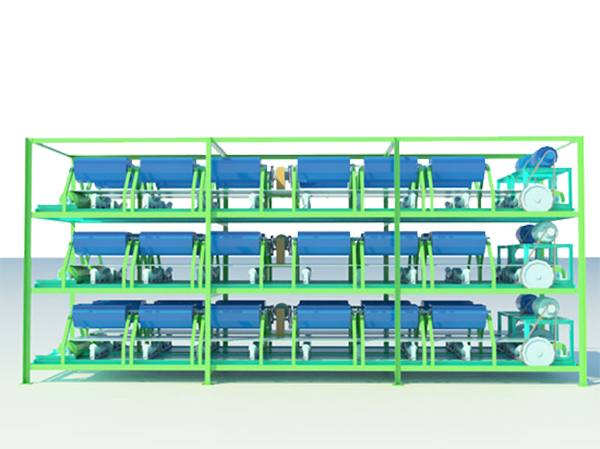

Drying adult mill

Product model:

Still thinking about it? If you want to know more,Please contact us!

Current Product Classification

Keywords

- Product Description

-

The principle and structure of the equipment is the design principle of the combination of advanced hot air circulation drying technology and high-intensity grinding machine. The equipment is mainly composed of drying chamber, crushing chamber, hot air circulation system, motor drive system and control system.

1, drying room: the use of good quality insulation materials, internal configuration of hot air generator, through the intelligent temperature control system to accurately adjust the temperature, to ensure that the adult evenly drying at the appropriate temperature, retain its nutrients at the same time, effectively kill harmful microorganisms.

2, crushing cavity: equipped with high-strength alloy cutting tools, through the high-speed rotation of the shear force, impact force will be dried after the adult instant crushing to the required size. The crushing cavity is designed reasonably, easy to clean, and prevents material residue.

3, hot air circulation system: the use of energy fan will be hot air circulation in the drying room, improve the utilization rate of heat energy, speed up the drying speed, while maintaining uniform temperature and humidity in the drying room, improve the drying effect.

4, motor drive system: the use of low noise, high efficiency motor, for the drying and crushing process to provide stable power support.

5, control system: integrated touch screen operation interface, to achieve one-button start, automatic adjustment of parameters, fault alarm and other functions, easy operation, high degree of intelligence.

Application areas and advantages

The drying adult mill is widely used in insect breeding, biological feed production, organic fertilizer manufacturing and other fields. Its significant advantages are reflected in:

1. Excellent efficiency and energy saving: by optimizing the hot air circulation system and intelligent temperature control technology, the drying efficiency is greatly improved, the energy consumption is reduced, and it is in line with the concept of green production.

2. Maintain nutrition: Gentle drying method can maximize the retention of protein, amino acids, fatty acids and other nutrients in adults, and enhance the added value of products.

3. Flexible and changeable: the crushing particle size is adjustable to meet different production needs. Whether it is the production of insect protein powder, insect feed, or the production of organic fertilizer, can easily deal.

4. Health and safety: fully enclosed design, effectively prevent external pollution, to ensure the health and safety of finished products, in line with food safety standards.

5. Intelligent operation: The intelligent control system simplifies the operation process, reduces labor costs, and improves production efficiency.

厨余垃圾现已作为我们生活垃圾的重要组成部分,拥有含量水高、易腐败的特点,若不进行及时处理,长时间的堆积不仅会导致细菌滋生,蚊虫增多,威胁人体安全,还会浪费其中富含的宝贵资源。对厨余垃圾的处理已成为当下重要课题,今天将从厨余垃圾在处理方法和设备选择上讲述,如何将厨余垃圾实现资源化利用。

1、处理方法:

厨余垃圾处理的方式可以通过好氧堆肥来处理,可以将厨余垃圾转化为有机肥原料。因厨余垃圾含水量高且易腐败的特点。而微米生物的厨余垃圾处理设备的核心工艺是微生物高温好氧堆肥技术,设备经过自动提升 - 称重 - 倒料 - 破碎 - 冲洗 - 脱水 - 发酵 - 自动出料的流程完成厨余垃圾的处理。在其发酵技术下,通过高温杀死病原菌,又将厨余垃圾中的有机物转化成有机肥原料;废油通过三相分离系统自动提取;废气废水处理后达标排放。

2、设备选择:

厨余垃圾处理设备分为就地式处理和集中式处理。就地式处理配套的是厨余垃圾一体化设备,将所有功能集合为一体,放置于在厨余垃圾产生点,进行就地处理。日处理量较小、占地面积小,适用于学校、单位、饭店、企业食堂等场所。

集中式处理分为三个系统,分别是预处理系统、微生物发酵系统和电控系统,其占地面积较大,日处理量较高,适用于乡、镇、县城、街道、市区、农贸市场等中大型处理场景。

Online consultation

We will contact you within one working day. Please pay attention to your email.