Share

Straw thermal spray treatment equipment

Product model:

Still thinking about it? If you want to know more,Please contact us!

Current Product Classification

Keywords

- Product Description

-

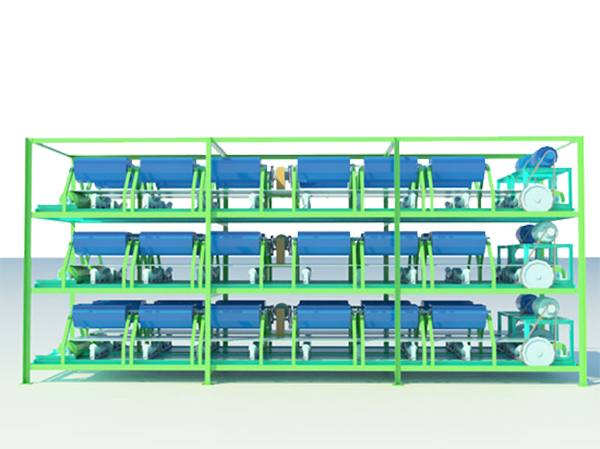

Straw thermal spraying treatment equipment is a specialized device used for processing crop straw, which changes its structure and chemical composition through thermal spraying technology, and improves its edibility and nutritional value. The following is a detailed introduction to the straw thermal spraying treatment equipment:

1、 Equipment principle

Straw thermal spraying treatment is the process of crushing crop straw into a certain length (which can also be mixed with cake, etc.), loading it into a feed thermal spraying machine, introducing a certain pressure of hot saturated steam, maintaining it for a certain period of time, and then suddenly reducing the pressure to allow the material to be sprayed out of the machine. During this process, the high temperature and high pressure environment will cause lignin to melt and fiber molecular chains to break, thereby changing the structure of coarse fiber molecules and achieving the goal of improving the edibility and nutritional value of straw.2、 Equipment construction and process flow

The straw thermal spraying treatment equipment mainly consists of a thermal spraying machine, steam boiler, pressure tank, discharge valve, relief tank, conveyor, etc. The general process flow is as follows:Raw material preparation: Cut the crop straw into a certain length through a grass cutter.

Material sealing: Put chopped straw into the storage tank, and then load it into the underground pressure tank in batches through the feeding funnel, and seal it.

Thermal spray treatment: Inject low and medium pressure steam provided by the boiler into the pressure tank (steam pressure generally ranges from 0.5 to 1.0 megapascal), and maintain it for a period of time (generally ranging from 1 to 30 minutes). During this process, straw undergoes physical and chemical changes in a high-temperature and high-pressure environment.

Pressure relief spraying: By controlling the discharge valve for pressure relief spraying, the processed straw is sprayed from the pressure tank and enters the relief tank.

Subsequent processing: The sprayed straw can be directly fed to livestock or pressed into shape for storage and transportation.

厨余垃圾现已作为我们生活垃圾的重要组成部分,拥有含量水高、易腐败的特点,若不进行及时处理,长时间的堆积不仅会导致细菌滋生,蚊虫增多,威胁人体安全,还会浪费其中富含的宝贵资源。对厨余垃圾的处理已成为当下重要课题,今天将从厨余垃圾在处理方法和设备选择上讲述,如何将厨余垃圾实现资源化利用。

1、处理方法:

厨余垃圾处理的方式可以通过好氧堆肥来处理,可以将厨余垃圾转化为有机肥原料。因厨余垃圾含水量高且易腐败的特点。而微米生物的厨余垃圾处理设备的核心工艺是微生物高温好氧堆肥技术,设备经过自动提升 - 称重 - 倒料 - 破碎 - 冲洗 - 脱水 - 发酵 - 自动出料的流程完成厨余垃圾的处理。在其发酵技术下,通过高温杀死病原菌,又将厨余垃圾中的有机物转化成有机肥原料;废油通过三相分离系统自动提取;废气废水处理后达标排放。

2、设备选择:

厨余垃圾处理设备分为就地式处理和集中式处理。就地式处理配套的是厨余垃圾一体化设备,将所有功能集合为一体,放置于在厨余垃圾产生点,进行就地处理。日处理量较小、占地面积小,适用于学校、单位、饭店、企业食堂等场所。

集中式处理分为三个系统,分别是预处理系统、微生物发酵系统和电控系统,其占地面积较大,日处理量较高,适用于乡、镇、县城、街道、市区、农贸市场等中大型处理场景。

Online consultation

We will contact you within one working day. Please pay attention to your email.